Individual plasma systems / plasma cleaner

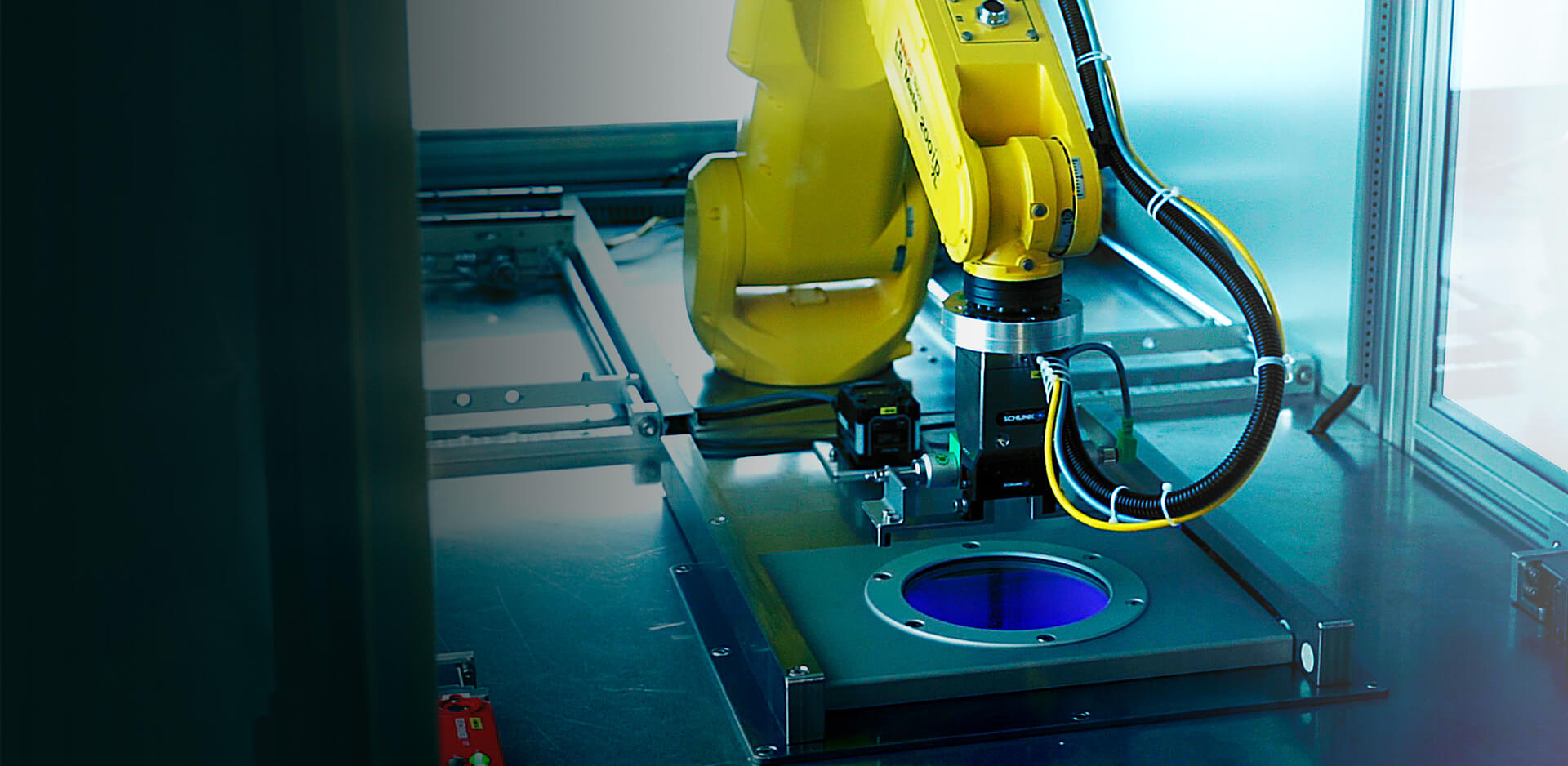

SPECIAL AND INLINE SYSTEMS FOR YOUR PRODUCTION

START AN INQUIRYThe design of our plasma systems is individually tailored to your needs. The determining factors are the intended material throughput, the size of the parts to be treated etc. A short-cycle system can be easily integrated into an existing production line. Another benefit: With a fully automated short-cycle system, the possibility of operator errors is excluded.