Vacuum drying cabinets: Precise drying for the highest demands

Vacuum dryer with temperature control

Start inquiry

Vacuum drying is a process in which moisture is removed from a substance by applying a vacuum in a vacuum drying oven. Compared to conventional drying methods, vacuum drying offers several advantages, especially for temperature-sensitive materials.

The basic principle of vacuum drying is based on the fact that volatile substances such as water or volatile organic compounds (VOCs) have a lower boiling point in a vacuum than at normal atmospheric pressure. This allows them to evaporate efficiently, enabling the material to be heated gently. In contrast to conventional methods, overheating of the material can be prevented. Vacuum drying in a vacuum drying oven ensures maximum purity for every area of application, as the vacuum eliminates any risk of contamination.

Diener electronic offers everything from a standardized modular system for vacuum drying ovens to customized vacuum dryers.

Vacuum dryer configuration

Chamber Material

The chamber material can be selected from aluminum or stainless steel.

With an aluminum chamber, there is less desorption, i.e., the release of foreign atoms or molecules from the surface of the chamber wall. This release of atoms leads to an increase in the negative pressure inside the vacuum chamber. Low desorption is a prerequisite for achieving a low target pressure in high vacuum/ultra-high vacuum applications.

Compared to an aluminum chamber, a stainless steel chamber (depending on the alloy) has better media resistance and also offers the possibility of freely designing your vacuum chamber in terms of size.

- Aluminum

- Stainless steel

Chamber Shape

The shape and size of the chamber varies depending on the component.

From individual components to be treated to large quantities, everything can be realized. You can choose between square, round, and bell shapes, but special shapes are also possible.

- square

- round

- bell

- special shapes possible

Temperature Control

In many cases, customer components are tempered to accelerate drying. Often, low-level heating is sufficient to compensate for the evaporative cooling and thus maintain the customer component at room temperature.

Depending on the medium to be dried, different temperatures and pressures are required within the vacuum chamber. Please ask our experts for specific advice.

- Temperature control plates with internal oil channels (-100 °C to +200 °C)

- Electric heating plates (up to +200 °C)

- Special electric heating plates (up to +400 °C)

- External temperature control elements (up to +60 °C)

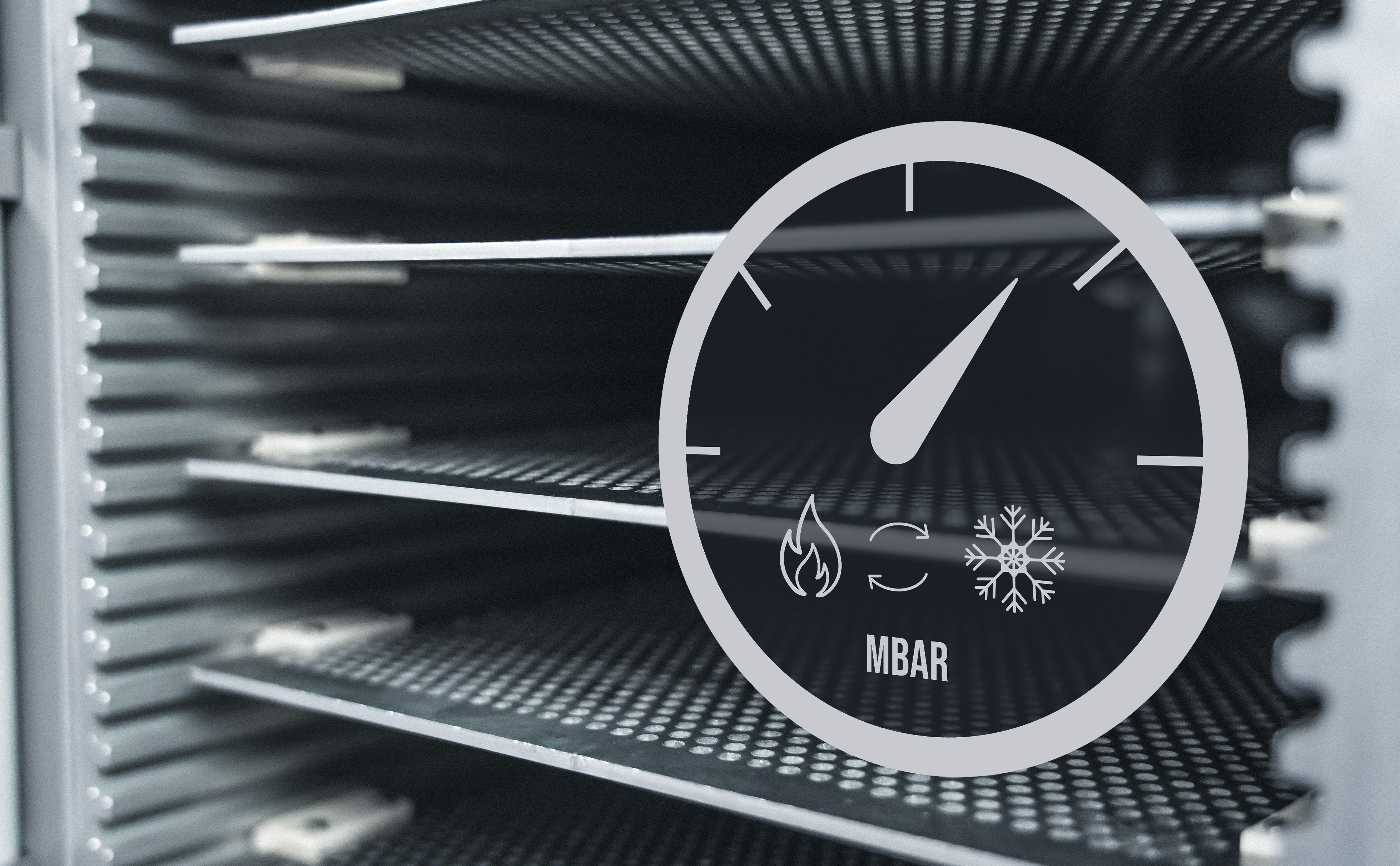

Pressure

Vacuum drying is determined by pressure as well as temperature. The lower the pressure in the chamber, the lower the boiling temperature. This means that certain media may boil at room temperature. This can even go so far that foreign matter can be removed directly from the customer's component by sublimation.

Our vacuum drying chambers can achieve any pressure from atmospheric pressure (approx. 1013 mbar) to beyond high vacuum (< 1x10-7 mbar).

For lower pressures, please ask our experts, who will be happy to advise you.

- Coarse vacuum

- Fine vacuum

- High vacuum

Control

Depending on the requirements of the process, different control options are available.

The Basic PC with 7-inch screen includes standardized programs, without archiving, and can be set to up to three pressures in coarse and fine vacuum.

If the Full PC with at least 15 inches is selected,

the options are tailored to your application and offer an alarm list, archiving, temperature ramps, and a connection option to an MES. A Full PC also allows the vacuum to be extended to high vacuum.

- Full PC

- Basic PC

Software and Interfaces

Diener electronic GmbH & Co.KG offers a comprehensive package where you get everything from a single source. We have our own software department, which enables us to design our own software ourselves and freely – entirely according to the customer's wishes.

The data transfer or software interface of the full PC serves as a connection to higher-level systems such as MES or SCADA. It is also possible to automate the vacuum drying cabinet with, for example, an automatic sliding door or the option of robot loading in an inline automation system.

- Analog interfaces

- Modbus

- OPC-UA

- PROFINET

- PROFIBUS

- EtherCAT

- Others available on request

Your vacuum drying oven

Variable design

The vacuum drying chambers from Diener electronic offer a wide range of options that can be differentiated into coarse, fine, and high vacuum with a pressure of up to

<10-7 mbar. The high-performance dryers guarantee gentle drying with controlled cleanliness and outgassing values thanks to their process stability.

Variable in their design, the vacuum drying ovens also offer a wide range of process options, such as working with a process gas, e.g., ventilation with nitrogen.

Temperature control for more possibilities

With vacuum drying chambers from Diener electronic, it is possible to run a process at different temperatures in order to accelerate the drying process in a targeted manner. The temperature control of the drying chambers enables flexible and application-specific treatment.

If a component needs to be heated more intensively, Diener electronic offers a solution with specially developed heatable product carriers.

Temperature-controlled product carriers enable rapid and targeted cooling after baking. Temperatures well below freezing are also possible. Vacuum drying chambers with temperature control offer efficiency and speed while ensuring maximum purity.

Control and inline integration

The control options of the vacuum drying cabinets enable customizable programs, archiving, and the setting of temperature ramps with the full PC control. Furthermore, the full PC control enables integration into inline automation. For inline integration, the drying oven can be automated with, for example, an automatic sliding door for robot loading.

For connection to higher-level systems, a software interface such as PROFINET or EtherCAT® is available.

- Gentle drying: Low temperatures protect temperature-sensitive materials such as food, pharmaceuticals, and plastics.

- Efficient drying: Vacuum drying removes moisture from the material quickly and evenly.

- Preservation of material properties: Color and structure are retained.

- Prevention of corrosion and contamination: The vacuum prevents contamination of the material.

- Modular system up to customer-specific systems.

- Interfaces: Communication options with higher-level systems.