High-end batteries

With short-cycle and in-line plasma pre-treatment for state-of-the-art battery systems

Start requestLong-term stable battery modules

The battery is the heart of an electric vehicle. In addition to the automotive industry, batteries are now an essential component in many industrial sectors, such as the PV industry (solar storage), mobile devices (smartphones, tablets, battery-powered tools), etc. The demands on the battery cell are therefore particularly high. Connections and thus the adhesion of the individual components not only influence the tightness, but also ensure battery thermal management, which defines the service life and efficiency of a battery system. From the production of the individual cells, starting with the anode and cathode, through process steps such as calendering, drying and cell assembly to cell finishing and thus the finished battery/battery module, Diener electronic's plasma and vacuum technologies are the recipe for success.

Diener electronic has many years of proven experience in the development of plasma processes and has also gained in-depth knowledge in this application. Derived from the standard processes of cleaning and activation, Diener electronic has developed silanization processes in which thin silane layers are chemically bonded to surfaces. In addition to CVD processes, this technology offers advantages in various industries, such as improved corrosion resistance in the automotive industry, optimal adhesion in the medical industry, and protection and insulation in the semiconductor/electrical engineering industry.

Improved adhesion of thin-film transistors

Silan coupling agents are versatile in surface treatments on a wide variety of materials. When plastic or glass is coated with silane, the surface is modified so that it interacts better with organic materials. This improves adhesion in organic electronic components, such as organic transistors. This can have a positive effect on performance. Organic thin-film transistors (OTFTs) are electronic components made of organic semiconductor materials and used to control electrical currents. Silanization is usually used to improve the adhesion of the organic semiconductor layer to the substrate. This chemically modifies the substrate surface, resulting in a smoother organic layer, which can improve the electronic performance of the component. Gas phase deposition is also used to create high-purity, uniform layers of materials that serve as electrical insulators or conductors in the structure of OTFTs.

Reducing surface adhesion

In addition to improving adhesion, silane coatings can also be used to reduce surface adhesion, e.g., in MEMS.

Microscopic mechanical parts benefit from a surface with low surface energy, e.g., through a silane coating, which reduces van der Waals forces, capillarity, or electrostatic forces in advance. This prevents potential blockages or unwanted adhesion.

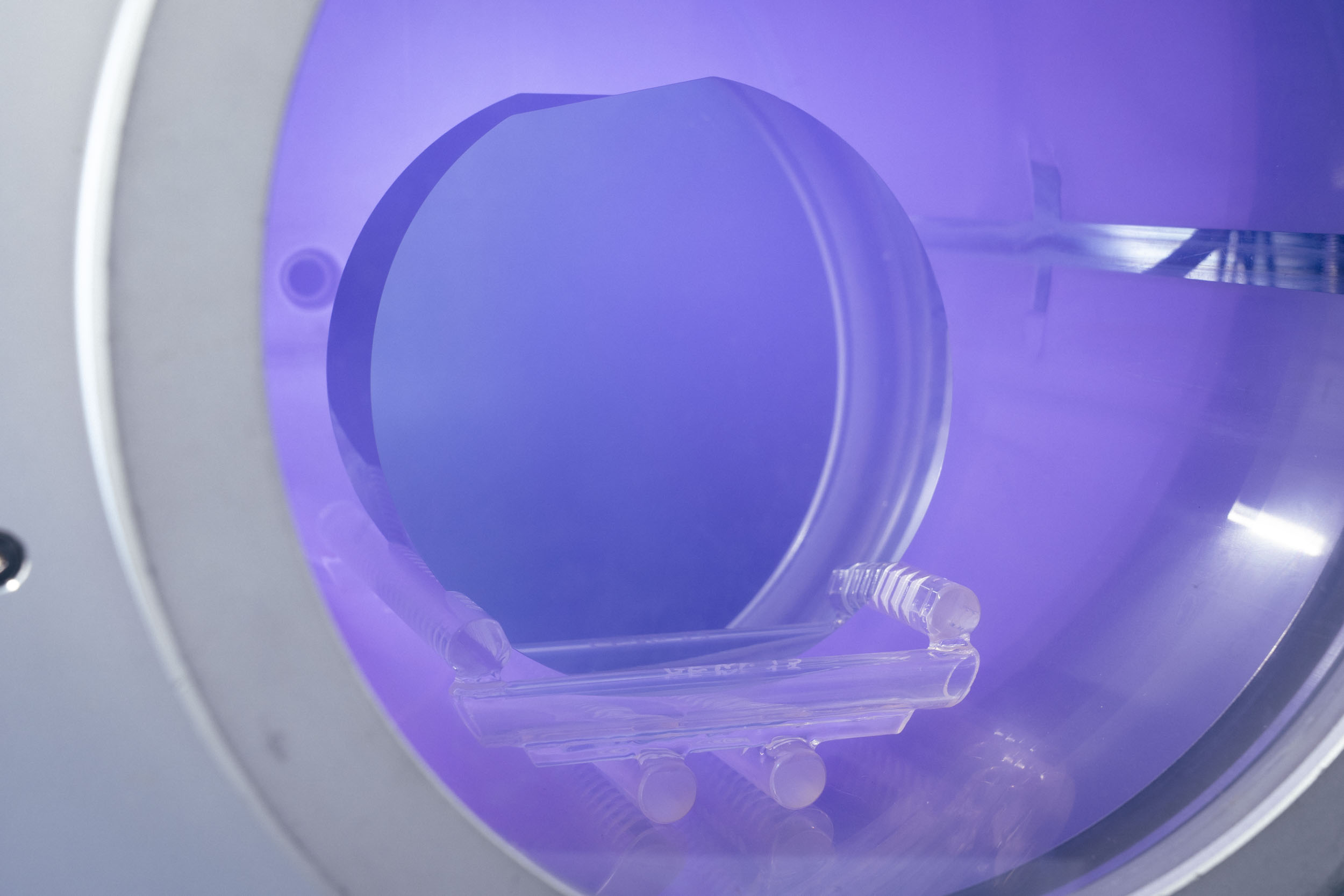

![[Translate to english:] Niederdruck-Plasmaanlagen Plasmasystem, plasmacleaner for laboratory and production, Nano](/fileadmin/user_upload/Produkte/Niederdruck-Plasmaanlagen/Plasmaanlage_diener-electronic_Nano.jpg)

Cleaning Wafers with Plasma

In many cases, it is necessary to subject the carrier film to plasma cleaning and activation before coating with the slurry. In principle, the material of the film (copper, aluminum, PEEK, etc.) is irrelevant and can be pretreated either in roll-to-roll low-pressure plasma systems or inline with rotating atmospheric pressure plasma nozzles(PlasmaBeam RT).

After coating and drying the carrier film and subsequent calendering, it must be cleaned and activated again. This ensures constant cell performance. The quality requirements for particle-free ultra-fine cleaning are also enormous for separator sheets and contacting. This makes the use of plasma technology the ideal pre-treatment step in terms of process reliability, environmental friendliness and cost efficiency.

Activate with hydrogen plasma

The subsequent module production requires a high degree of activation of the individual components in many production steps. For example, the finished cells must have optimum surface properties to enable reliable bonding or potting. Similarly, the contacts (pins) for the electrical connection of the battery cells(wire bonding) must be absolutely free of dust and grease. The use of our plasma devices for surface activation/cleaning is therefore not so much recommended as necessary in order to produce high-quality battery modules. Both atmospheric pressure plasma systems (PlasmaBeam) and low-pressure plasma systems are suitable for this pre-treatment. Plasma systems in the low-pressure range have decisive advantages over atmospheric pressure systems. For example, the removal of oxide layers on copper or nickel surfaces with vacuum plasma is child's play and is already a standardized process in many industrial sectors. In contrast, such results can hardly be achieved with atmospheric pressure systems.

Activate with steam

Similar to activation with hydrogen, activation with saturated steam also works. Unlike hydrogen, this process is particularly gentle and kind to the surface. The ionized water gas is directed onto the surface and can penetrate the microscopic structure of the surface, removing silicon oxides. This step results in a clean surface that is ready for reaction. Ideal for subsequent coating processes such as the CVD process.

Evaporate silane

The chemical vapor deposition (CVD) process is one of the best-known applications of silane evaporation. In this process, silane is evaporated under vacuum and applied as a gas to a surface to form a thin silicon layer. Silicon can achieve various effects in this way. These include: changing the semiconductor properties, insulation, and protection between the circuits. Chemical vapor deposition offers optimal conditions because, among other things, it enables controlled application of the silicon layer, gas phase epitaxy, and can apply it in a particularly homogeneous and conformal manner.

The dosage of the silane compounds is crucial for the process, as it defines their quality and efficiency. It is very important to concentrate the appropriate silane types correctly, to take environmental influences such as temperature and humidity into account, and to set the reaction time correctly. The software helps with this and enables precise adjustment of the parameters. Diener electronic is happy to advise you on how to optimally adjust your process.