Plasma pretreatment step for optimum adhesion

Bonding is a process for joining materials that can be prepared and optimized using plasma technology. Plasma treatment is a crucial step in this process to ensure optimum adhesion.

Optimized bonding using plasma is used in many industries, such as aerospace, consumer goods, packaging, automotive, and medical technology, where there are high demands on sustainability, durability, and adhesive strength. International NATO STANAGs specify the requirements for adhesive bonding in the military sector, as do numerous standards such as the VG standards (defense equipment standards). Plasma surface treatments with equipment from Diener electronic are essential in order to meet the requirements for adhesive bonding.

What is plasma

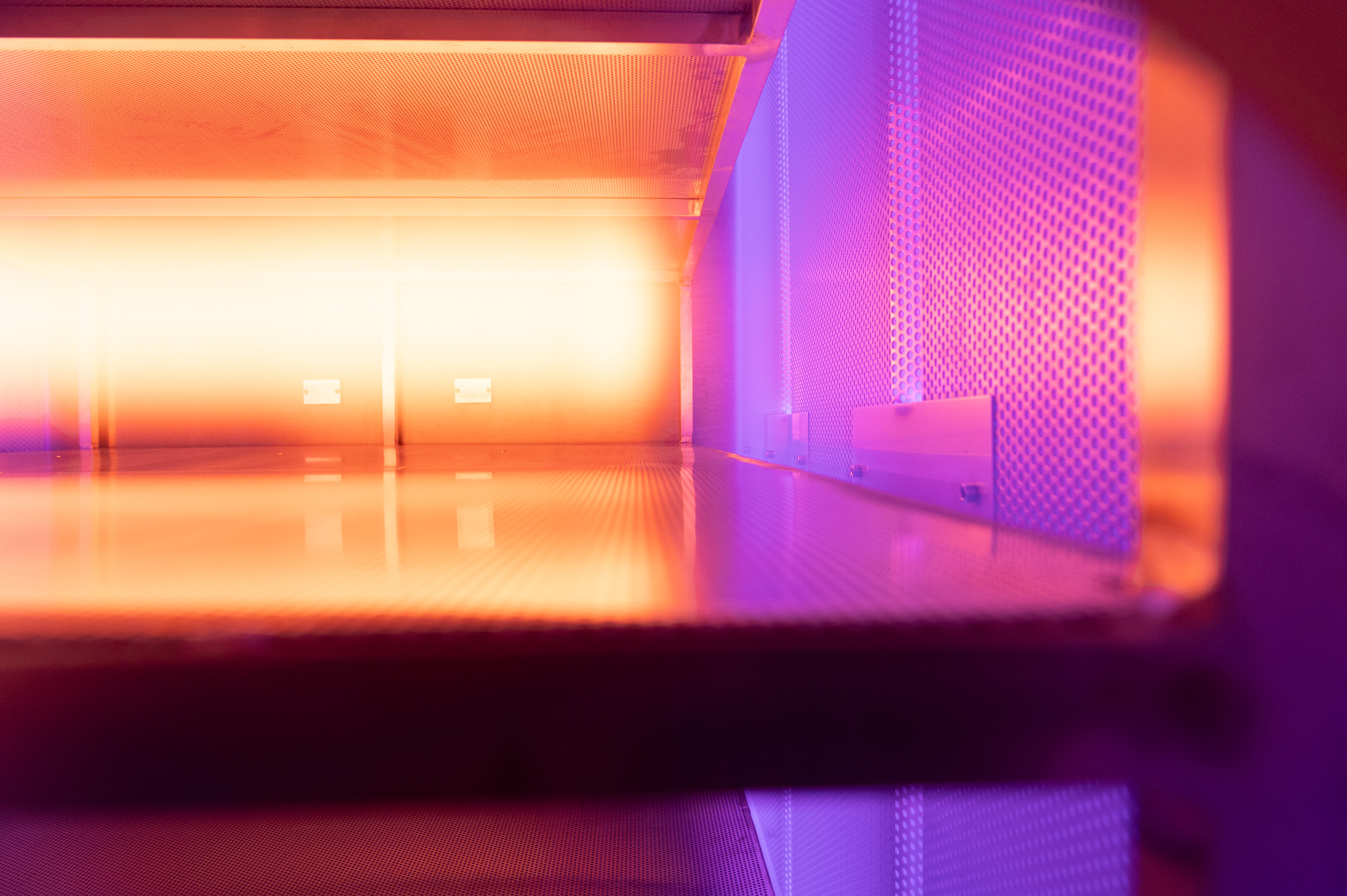

Plasma, a high-energy, ionized gas, is a versatile technology for cleaning, activating, etching, and coating surfaces. Plasma treatments are ideal as a pretreatment for further bonding processes.

The duration of the plasma process determines the intensity of the surface treatment. In the first phase, organic contaminants are removed. As the treatment time increases, the surface begins to activate, significantly improving adhesion properties and creating optimal conditions for subsequent bonding processes. Thanks to its many years of expertise, Diener electronic can perfectly adjust the surface treatment and its degree.

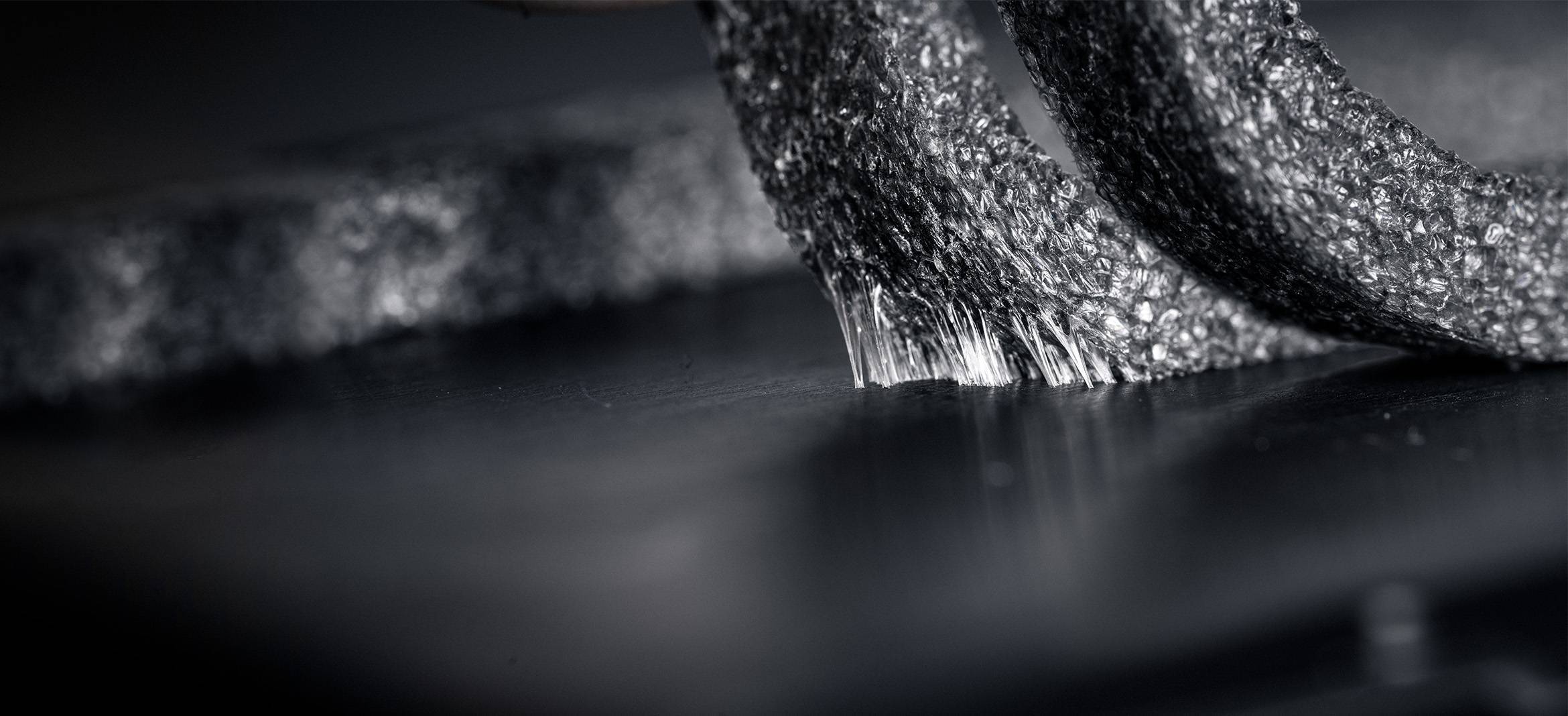

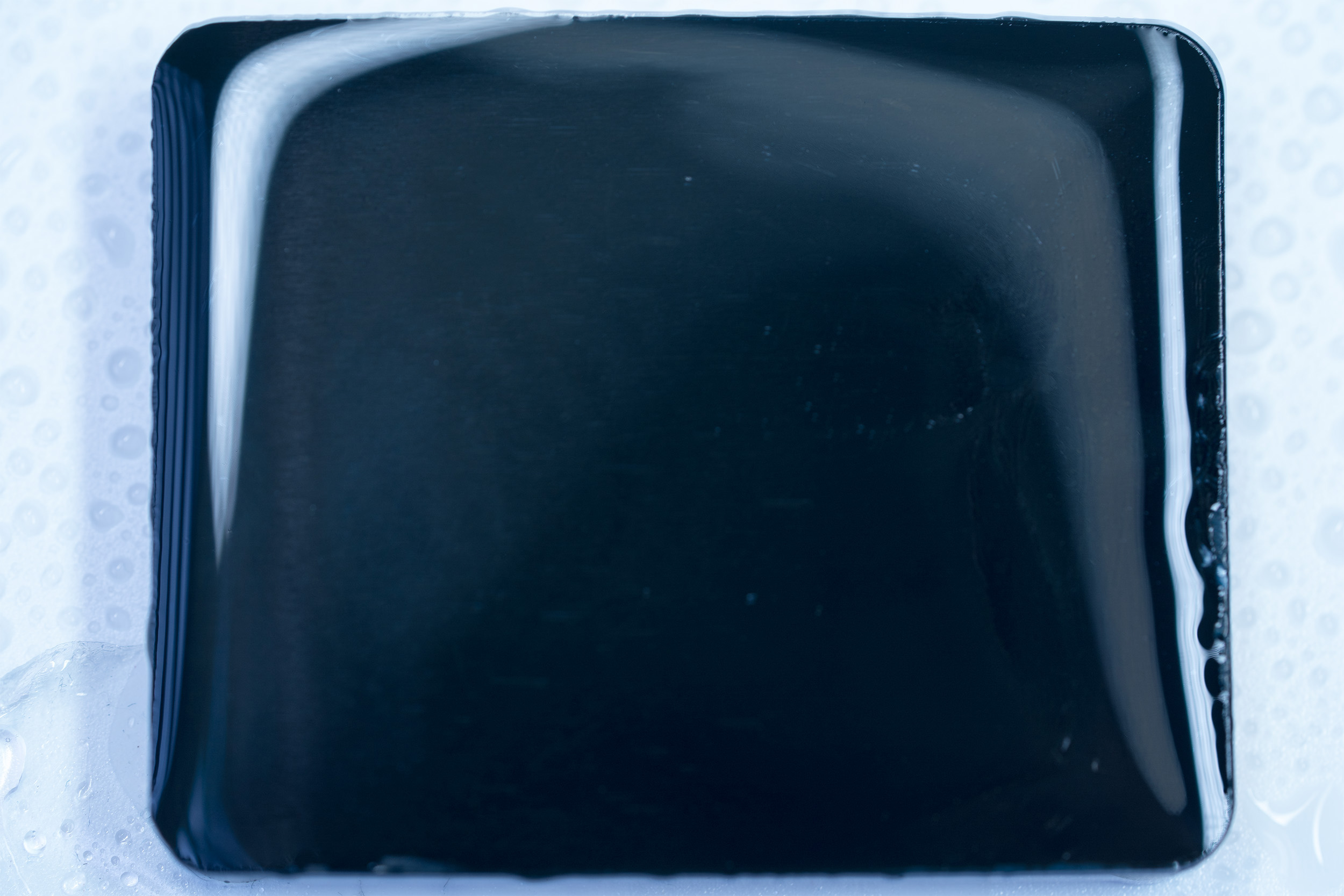

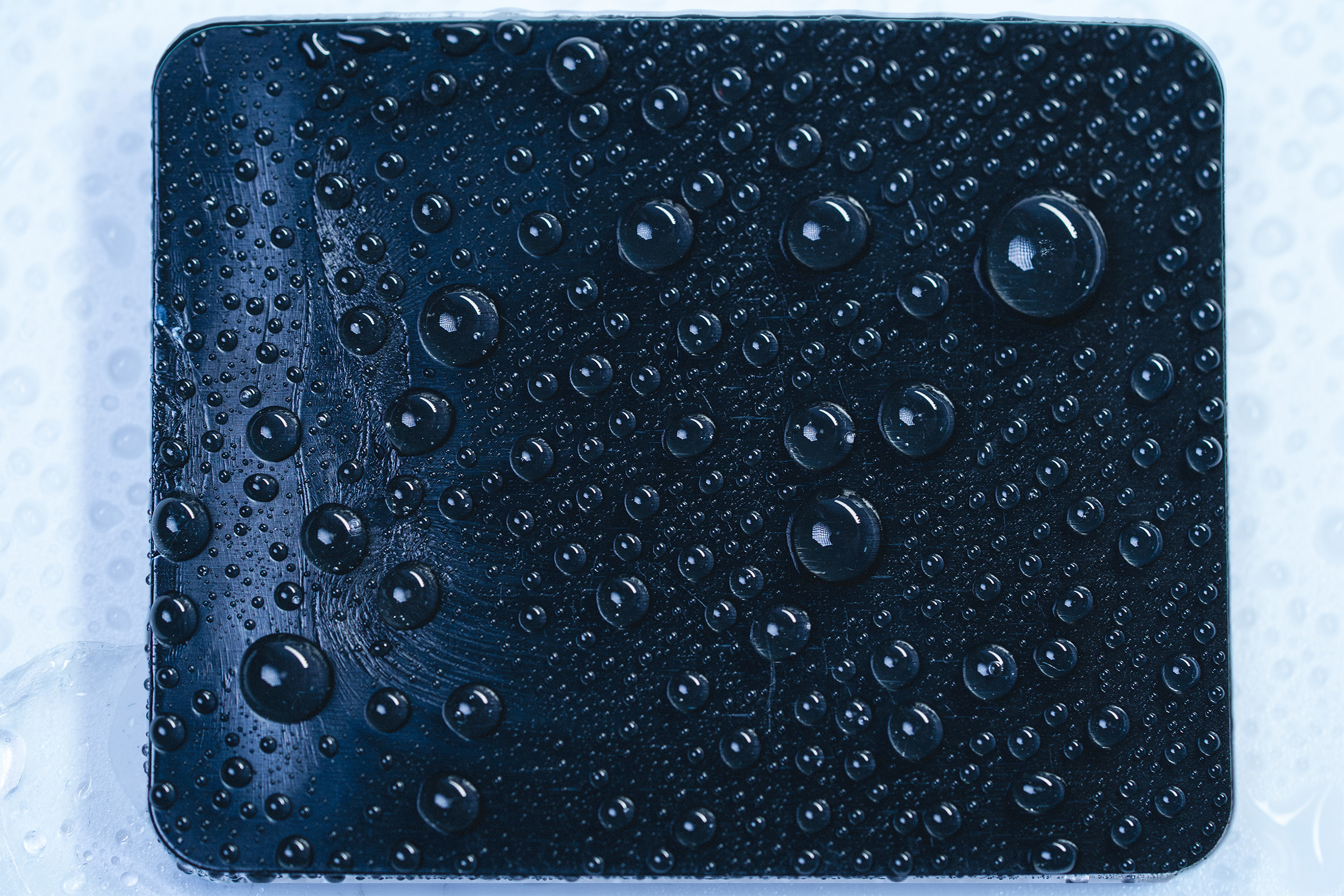

When bonding, two components are joined together with an adhesive. However, many plastics or components are inherently non-polar. Due to the hydrophobic properties of the surfaces, bonding without pretreatment is often impossible. Plasma treatment specifically modifies the surface, creates polar functional groups, and thereby improves wettability, resulting in significantly more stable adhesion.

Activation of plastics

Plastics such as PP, PE, PA, and POM are mass-produced plastics that are particularly nonpolar. When treated with oxygen or even just ambient air plasma, a chemical bond is formed during activation after cleaning. Oxygen atoms react with the hydrocarbon compound on the component surface to form a strong chemical bond. The polar groups on the surface increase the surface energy of the component and thus also its wettability. This is optimal preparation for subsequent printing, painting, or bonding. Plasma also helps casting compounds to meet requirements by preparing the component surface. The series of standards VG 95343-10, VG 95343-12, and VG 96927 specify requirements for processing, curing, porosity, and freedom from bubbles. The use of plasma technology supports compliance with standards through improved wettability by means of surface activation, resulting in uniform flow and fewer air pockets.

Structural bonding

Plasma treatments are used for structural bonding, e.g., of panels in vehicle construction or for creating connections in touch monitors in electronics. This process replaces solvents and primers, traditional pretreatment methods that are often harmful. Structural bonding is an environmentally friendly, high-performance, and economical adhesive bond. Diener electronic helps to ensure that these processes and treatments comply with the VG 95211 standard, which specifies requirements for adhesive bonds and surface preparation. In electronics manufacturing, for example, both bonding and potting processes are used. While bonding is optimally prepared by plasma surface activation, casting compounds for electronic assemblies must comply with specific standards, such as the VG 95343 series or VG 96927, in order to ensure their protection. These standards specify requirements for chemical resistance, electrical insulation, and processing conditions for casting materials. STANAG 4671, on the other hand, specifies requirements for structural bonding and the airworthiness of unmanned aerial systems (UAS).

Activation of metals

Although metals have a higher surface energy than plastics, they can exhibit hydrophobic properties due to oxide layers or organic contaminants. Plasma treatment removes these and significantly improves wettability. This is relevant for soldering processes in electrical engineering, for example. Plasma can increase the surface energy of metals and enable the wettability of solder alloys. Pre-treatment in the form of cleaning and removal of organic contaminants and oxide layers is of great importance here. Plasma treatments in hydrogen plasma can significantly reduce contaminants that are otherwise difficult to remove.

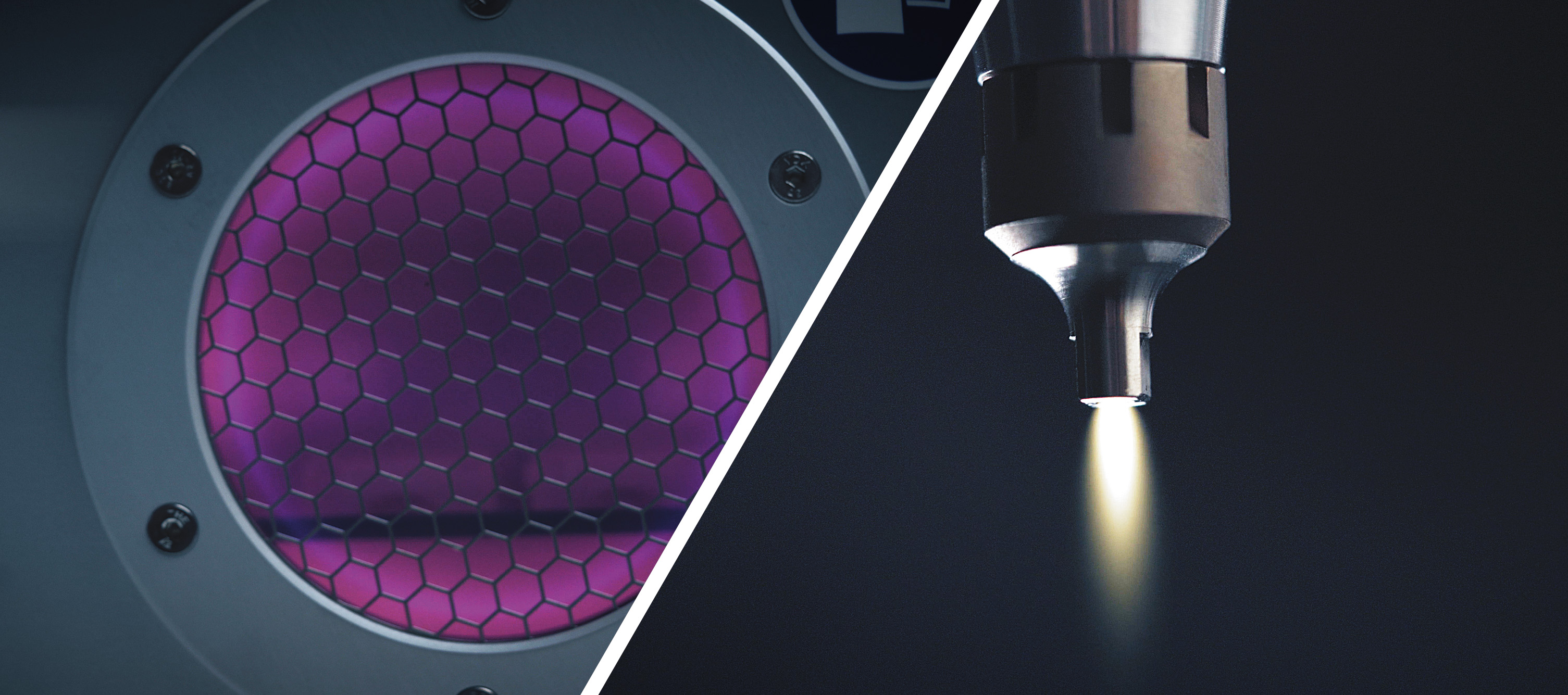

Plasma treatments in the low-pressure or atmospheric pressure range

Diener electronic has proven expertise in the areas of plasma treatments in low-pressure plasma and also atmospheric pressure plasma. Industries that can process large quantities quickly benefit from low-pressure plasma technology. The vacuum chambers, which are specifically tailored to the customer's individual needs, enable almost any component in any shape and substance to be treated. If more selective treatment is desired, atmospheric pressure plasma technology is the ideal solution. The variable nozzles enable selective and automated treatments and their immediate follow-up treatments.